Making its global debut at the 2010 Geneva Motor Show, the Hyundai HED-7 concept car carries forward the company’s evocative new form language, ‘fluidic sculpture’. The flowing, elegant lines not only create a bionic, futuristic shape, but also contribute to exceptional aerodynamics, helping to reduce the car’s CO2 output to just 85 g/km and fuel consumption to only 3L/100km.

Hyundai’s first diesel hybrid powertrain is also a key factor in delivering such an environmentally-conscious return, as is the application of next-generation materials and technologies developed in cooperation with leading chemical company BASF.

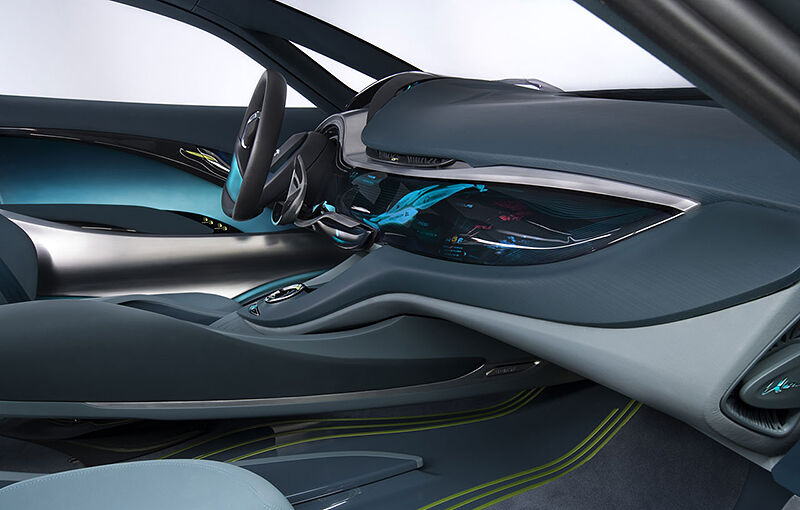

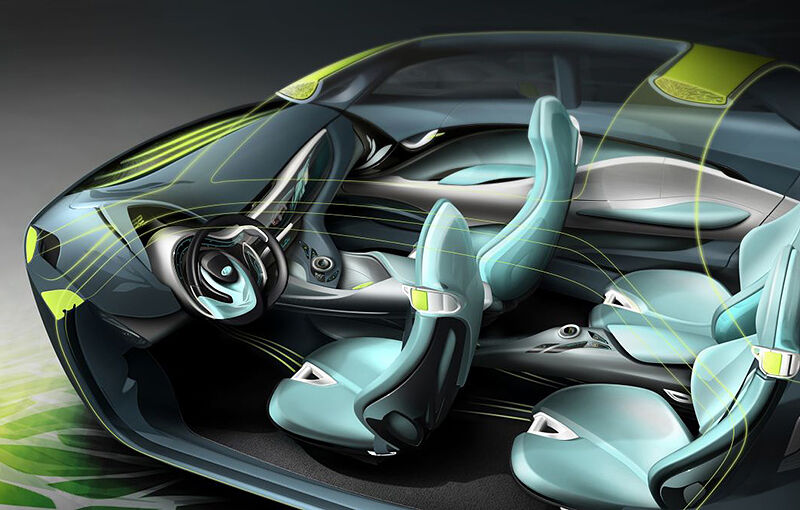

With an overall length of 4,780 mm and a 2,800 mm wheelbase, the HED-7 brings new ideas and a pioneering form to the traditional European D-segment. The dramatically-sculpted forms of the interior and exterior make for a striking sports sedan, and its width and height (1,850 mm and 1,420 mm respectively) give it an athletic stance.