Hyundai Worldwide Global Navigation

- Go to Global Distributors page

- KR

-

Search

Hyundai Motor Group announced the appointment of Dr. Minwoo Park, a global expert in autonomous driving technology, as Head of its Advanced Vehicle Platform (AVP) Division and CEO of 42dot to strengthen software-defined vehicles (SDV) and autonomous driving-based vehicle software competitiveness.

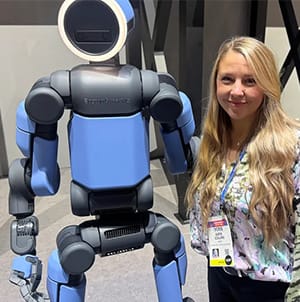

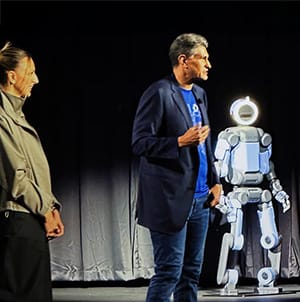

Hyundai Motor Group (the Group) affiliate Boston Dynamics’ Atlas has won CNET Group’s ‘Best Robot’ award as part of the Best of CES™ 2026 awards.