Unlocking the potential of electric cars: How battery breakthroughs are shaking up the sector.

As electric vehicles (EVs) continue to grow in popularity, the role of battery technology will become increasingly important among consumers and car manufacturers.

In the year 2050, Bloomberg NEF predicts that even with no further incentives for electric cars, EVs will make up 88% of passenger vehicle sales. With batteries representing the ‘heart’ of the EV, such a level of electric car dominance will only be achievable if advances in battery technology keep up.

Fortunately, breakthroughs in battery development are seeing EV performance and range consistently improve to a point where the woes of range anxiety and long charging times are quickly being placed in the rear-view mirror.

Our latest EV for example, the IONIQ 6, (launching in Australia in 2023) has the longest range of any Hyundai EV to date – tipping over the 600km mark and charging in a mere 18 minutes (350kW charger; from 10% to 80%) – barely enough time to enjoy a coffee!

Achieving such a range is in large part due to advancing lithium-ion battery tech, the most common EV battery which features in all Hyundai’s EV models. However, this isn’t the only battery we expect to play a role in realising a world where EVs represent the majority of cars on the road.

Solid-state batteries are seen as the next step with the potential to deliver even more range, quicker recharging and extended battery life. They have yet to make the jump to commercialisation, however hold enormous promise for the future of EVs.

While critical to performance improvements, advances in battery technology need to be teamed with progress in the vehicle platform itself, with dedicated EV platforms having a distinct advantage over their traditional counterparts.

With the shift to EV’s accelerating, let’s take a look at some of the advances taking place in battery tech and Hyundai’s developments in this space.

What are the common batteries in an EV?

First of all, which batteries do EVs typically use? Well, there are four common types, including lithium-ion, nickel-metal hydride, lead-acid and ultracapacitor batteries.

Each one has its advantages and disadvantages, however its lithium-ion batteries that are currently the industry norm for EVs. They are also found in many consumer electronic items like smartphones, tablets and laptops.

Lithium-ion batteries have a high energy per unit mass compared to other batteries. They also have the advantages of a high power-to-weight ratio, energy efficiency, high-temperature performance, and low self-discharge.

Hyundai uses lithium-ion batteries in our EV models. In fact, we are scaling up the manufacture of these batteries by opening a facility in Indonesia in 2024 which will produce enough lithium-ion battery cells for over 150,000 electric vehicles annually.

While lithium-ion dominates the EV sector today, many analysts tip the next frontier could be the solid-state battery.

Solid-state batteries; the future for EVs?

Inserting more battery cells into the battery increases the vehicle range, but it also makes the vehicle heavier and more expensive. Finding the point of compromise that best fits the vehicle model is key.

Recent advances in lithium-ion battery technology have driven a gradual rise of battery energy density, however solid-state batteries could see the sector make an enormous leap forward in driving range.

Hyundai is partnering with US start-up, Factorial Energy to test their novel solid-state battery technology and its integration in Hyundai EVs. The companies will integrate the new technology at the cell, module and system levels, perform vehicle-level integration, and co-develop specifications for manufacturing Factorial’s batteries.

For more information, see our section on battery types.

Battery TypesFirst of all, which batteries do EVs typically use? Well, there are four common types, including lithium-ion, nickel-metal hydride, lead-acid, and ultracapacitor batteries.

Each one has its advantages and disadvantages, however its lithium-ion batteries that are currently the industry norm for EVs. They are also found in many consumer electronic items like smartphones, tablets and laptops.

Lithium-ion batteries have a high energy per unit mass compared to other batteries. They also have the advantages of a high power-to-weight ratio, energy efficiency, high-temperature performance, and low self-discharge.

Hyundai uses lithium-ion batteries in our EV models. In fact, we are scaling up the manufacture of these batteries by opening a facility in Indonesia in 2024 which will produce enough lithium-ion battery cells for over 150,000 electric vehicles annually.

While lithium-ion dominates the EV sector today, many analysts tip the next frontier could be the solid-state battery.

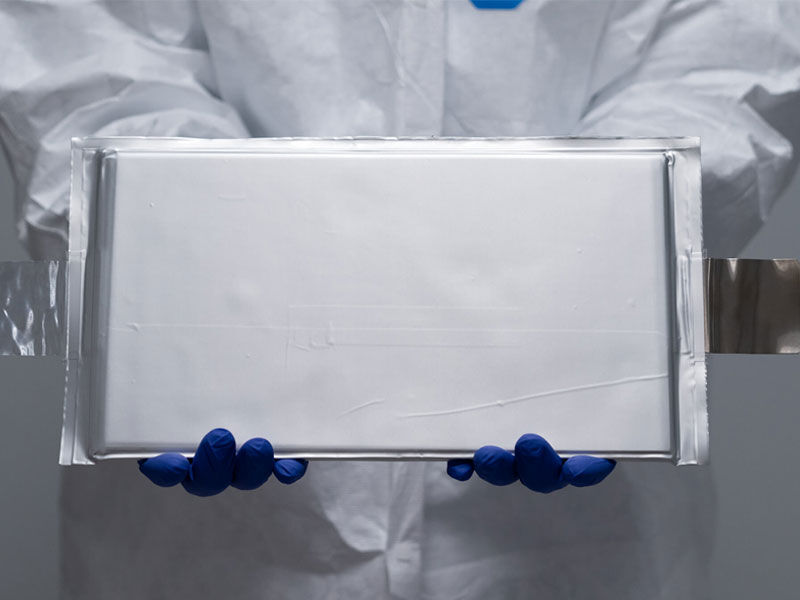

Factoria’s solid-state battery (Credit: Factorial Energy)

Factorial’s technology leverages solid electrolyte material that enables safe and reliable cell performance with high-voltage and high-capacity electrodes and has been scaled in 40Ah cells that perform at room temperature.

The technology extends driving range by 20 to 50% and is drop-in compatible for easy integration into existing lithium-ion battery manufacturing infrastructure.

We believe the technology could make the transition to solid-state batteries seamless and cost-effective, and in turn, unlock the mass adoption of EVs globally.

In parallel to battery advancements, we also believe utilising dedicated electric car platforms will be critical to drive improvements in EV battery performance.

What is a dedicated EV platform?

Platforms designed for electric cars have serious ramifications on an EV’s cost-efficiency and quality assurance, which explains why many global manufacturers have been focusing their R&D capacity to develop a single platform.

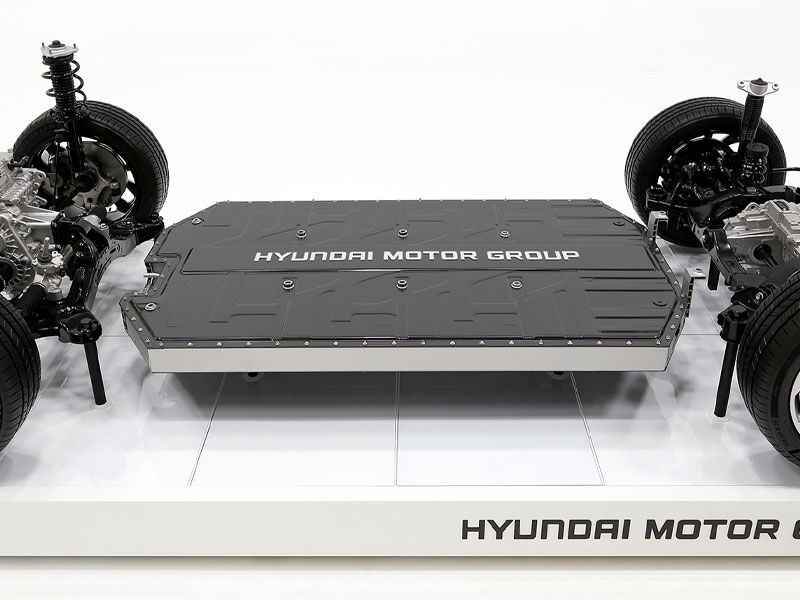

Hyundai’s electric Global Modular Platform (or E-GMP for short) EV platform architecture has been developed as a dedicated EV platform.

Hyundai’s dedicated EV platform, E-GMP

Compared to existing platforms—which were mere redesigns of internal combustion engine (ICE) vehicle platforms—our E-GMP is distinguished by many advantages: flexibility in development, EV-optimised structural design, standardised high-capacity battery system, longer range, futuristic aesthetics and interior spaciousness.

The platform also enables EV owners to unlock the energy from their batteries in new ways through applications like Vehicle-to-Grid (VTG).

Unlocking energy from an EV

Hyundai is developing Vehicle-to-Everything (V2X) technology to further integrate renewable energy and EVs into society and reduce the strain on local electricity networks.

One of these technologies is V2G which enables energy that is already stored in the battery packs of a battery electric vehicle (BEV) to be provided to the electricity network.

As well as stabilising the grid, the energy stored in a BEV feeds the grid to assist in managing energy demand during peak times and emergencies.

Development projects for V2G are currently in progress at Hyundai and we plan to announce an upcoming BEV model with V2G technology.

We believe the energy landscape will change dramatically with the integration of BEVs into the grid. Not only will BEV owners contribute to the stabilisation of their local grid, but also to a steadier renewable energy supply.

During high-peak times when large amounts of energy are drawn from the grid, BEVs can return energy to the local infrastructure and help even out the demand. Owners can then recharge their BEVs at a lower cost during off-peak hours.

However, BEVs are not limited to pushing energy to the grid; they can power homes and buildings as well. V2X is the umbrella term used to describe the additional value of BEVs during times of non-use, including V2G as well as other use cases like Vehicle-to-Load (VTL).

Hyundai enters the V2X ecosystem

Hyundai has set its sights on securing global leadership in vehicle electrification by 2025. Underpinning this will be our goal to introduce more than 11 BEV models built upon E-GMP.

One pillar of the company’s strategy to achieve this is developing cleaner energy solutions and technologies, including advanced battery technology and V2X.

By improving batteries, building more charging infrastructure, and enhancing vehicle performance, modern-day EVs will not only help the future environment but also provide satisfying performance for all.

At the core of future mobility is of course the battery and we look forward to bringing innovative developments in this space over the coming years that will ultimately provide our customer with a better, cleaner driving experience.